Uncompromising quality is one of the Prada Group’s key attributes, and this has been reinforced by the new Levanella Quality Control Centre near Arezzo in Tuscany, which opened in 2015 and which has seen an increase in both the number of employees and the range of tools used. The aim is to be absolutely certain that the quality of the finished product meets the high standards set by the group.

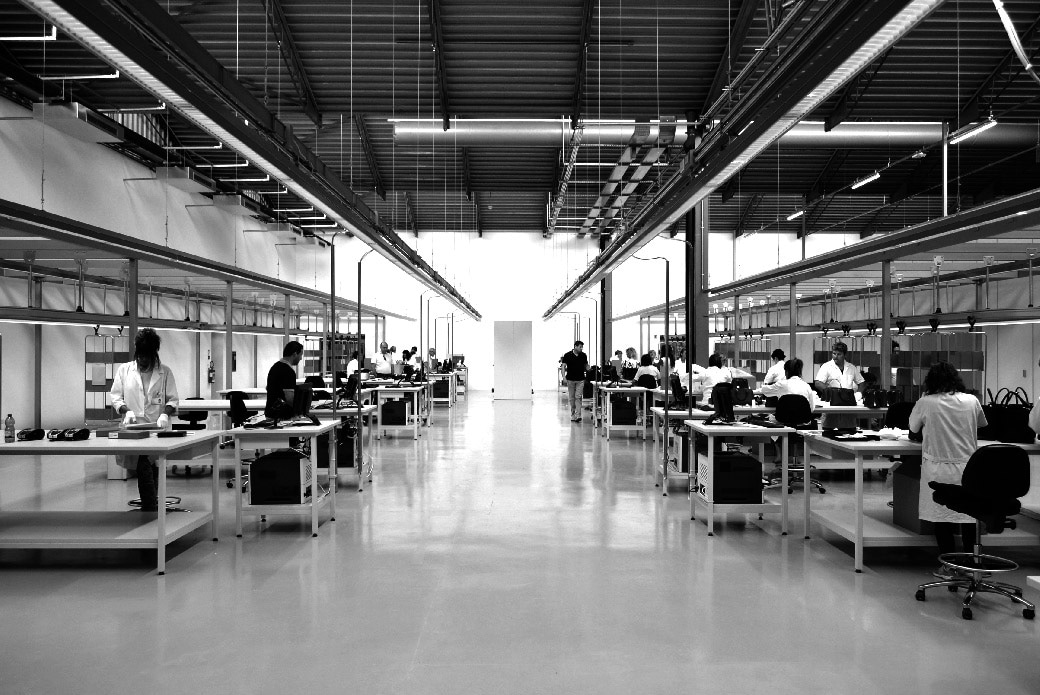

All aspects of the department were designed to optimise efficiency and to allow employees to respond attentively to the checks, identifying any defects in the production. Particular attention was therefore given to lighting, to ensure the products can be viewed correctly, and to the workbenches, which are coated in special materials to avoid the risk of damaging the products while they are being examined. In addition, workers can only handle the products if they are wearing specially designed white gloves.

The department has 48 members of staff and is divided into eight work areas, each with two workbenches. Three people work at each workbench: an expert tester and two finishers. The bags are transported to the work areas in trays along an automated conveyor belt, and every last detail of each item is examined. If approved, the tester signs digitally to certify the product, whilst any items that do not meet the required quality standards are sent back to the manufacturing department to be replaced.

The department can test approximately 2,800 items a day, and has a minimum percentage discard rate to ensure the quality of the final product sent to shops remains high.

The Prada Group – always offering uncompromising quality.